Food Technology Laboratory

Responsible: Dr Carlos Prentice Hernández

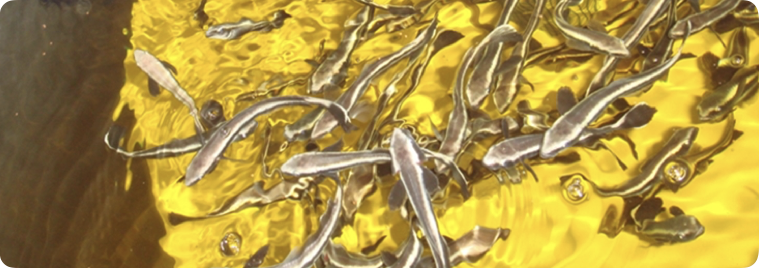

Detailing of the physical infrastructure: The sector is related to the development of processes for obtaining value-added products from fish of low commercial value and uses the support of the Research Program in Processing of Marine Products, in the facilities and infrastructure. structure of the Food Technology laboratories and the Fish Processing Unit, which add up to an area of ± 200 m 2 , located on the Campus City of FURG, dedicated to teaching, research, development and innovation.

Food Technology Laboratory (LTA): It is the central execution laboratory and provides the following equipment for use in the program: A glass reactor with real capacity for 1 L with automatic control and built-in ultra-thermostatic bath, two glass reactors with a 1 L jacket, a reactor glass with a 2 L jacket, a stainless steel reactor with a 5 L jacket, a spectrophotometer for UV / V use, a texture analyzer, a colorimeter, a bench freeze dryer, an ultrafreezer, a refrigerated shaker / shaker, a bench-top centrifuge, two vacuum pumps, two propeller shaft agitators, a rotary evaporator, an automatic protein digester, an automatic protein distiller, an automatic fat extractor, a 510 L horizontal freezer, a 250 vertical upright freezer L, a 340 L refrigerator, an analytical balance, two semi-analytical scales,two stainless steel tanks, among others.

Fish Processing Unit (UPP): UPP has the following equipment as a pilot plant for processing meat and fish in general: a meat and bone separator, two semi-industrial meat grinders, a semi-industrial cold refiner-extruder, two mixers industrial units of 2 and 10 L, a 25K hydroextractor, a 10 kg cutter, a manual press, a vacuum sealer using gases, an industrial air compressor, a bench oven with circulating air circulation, a refrigerated centrifuge floor, a mini extruder for polymers, two horizontal fillers of 0.5 and 10 L, two stainless steel work tables, two stainless steel washing tanks, a scale ice maker with a 70 kg tank , a semi-industrial oven, a dough divider, a freezing cabinet and a semi-industrial refrigerator.